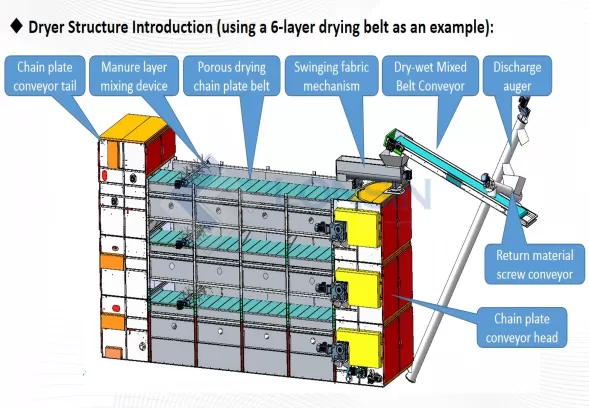

The ingredients in the wet state enter the component selection device through the component belt, lay on the porous drying plate, and then the hot air discharged from the shell or the independent pine through the dry rack to transport the air to the dryer, the air through the cardboard, take away the moisture of the wet layer, play a drying effect.

The moisture content of fresh chicken manure is reduced from 80% to 20%.

Since there is no fermentation process for drying, the original organic matter of the crops is well preserved. No additional materials are needed.

After drying, the odor can be eliminated, significantly improving the environment.

The dried poultry manure can also reduce fine dust and pests and diseases.

Its volume is also reduced, significantly lowering transportation costs.

The dried poultry manure contains a higher content of organic matter, which can be used as organic fertilizer or as fuel.

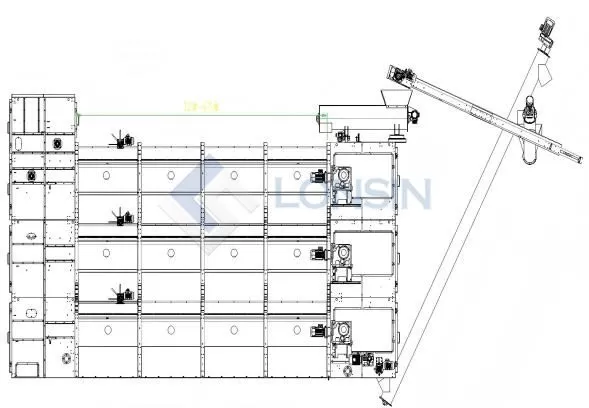

This equipment uses the manure conveying system to transfer the chicken manure to the multi-layer chain plate cloth material flipping system, the waste heat from the cooling fan in the chicken house or the independent air supply system is used to dry the feces. After drying the moisture content of chicken manure from 80% to 20% , can be sold immediately or long-term storage. The product is dried without fermentation process, without adding any excipients, and the organic matter which is beneficial to crop nutrition is not destroyed. At the same time, the organic matter in dry chicken manure is balanced, suitable for all kinds of crops, vegetables and fruits. After drying, the chicken manure does not produce odor, which can not only solve the air pollution caused by the smell of the manure and the problem of mass transportation, but also make the chicken manure difficult to be disposed of become valuable and increase the income.

Equipment structure

Control structure

Conveying structure

Mixing structure

Heat source selection

Customers can choose a suitable heat source based on local energy supply, cost budget, and environmental protection requirements.

The heating method of the heat source can also be customized, such as direct heating or indirect heating.

Equipment structure

From simple manual control to fully automatic control, customers can choose equipment with different automation degrees according to their production needs and staffing.

The functions of the automatic control system can also be customized

Appearance design

The appearance color, shape, etc. of the equipment can be customized according to customer requirements to meet the customer's personalized needs and coordination with the on-site environment.

E-mail:

lonsinliu@163.comPhone:

+86 152 6556 9399

WhatsApp:

+86 152 6556 9399